Breakthrough tech deal to develop new medical implants

New medical implants will be developed following a ground-breaking €312,000 technology deal. I-Form, the SFI Research Centre for Advanced Manufacturing, a leader in 3D metal printing, has signed a four-year agreement, with Shannon-based PBC BioMed, the medical device design and development company. The I-Form research team will be led by Prof Nicholas Dunne and Dr Tanya Levingstone at DCU.

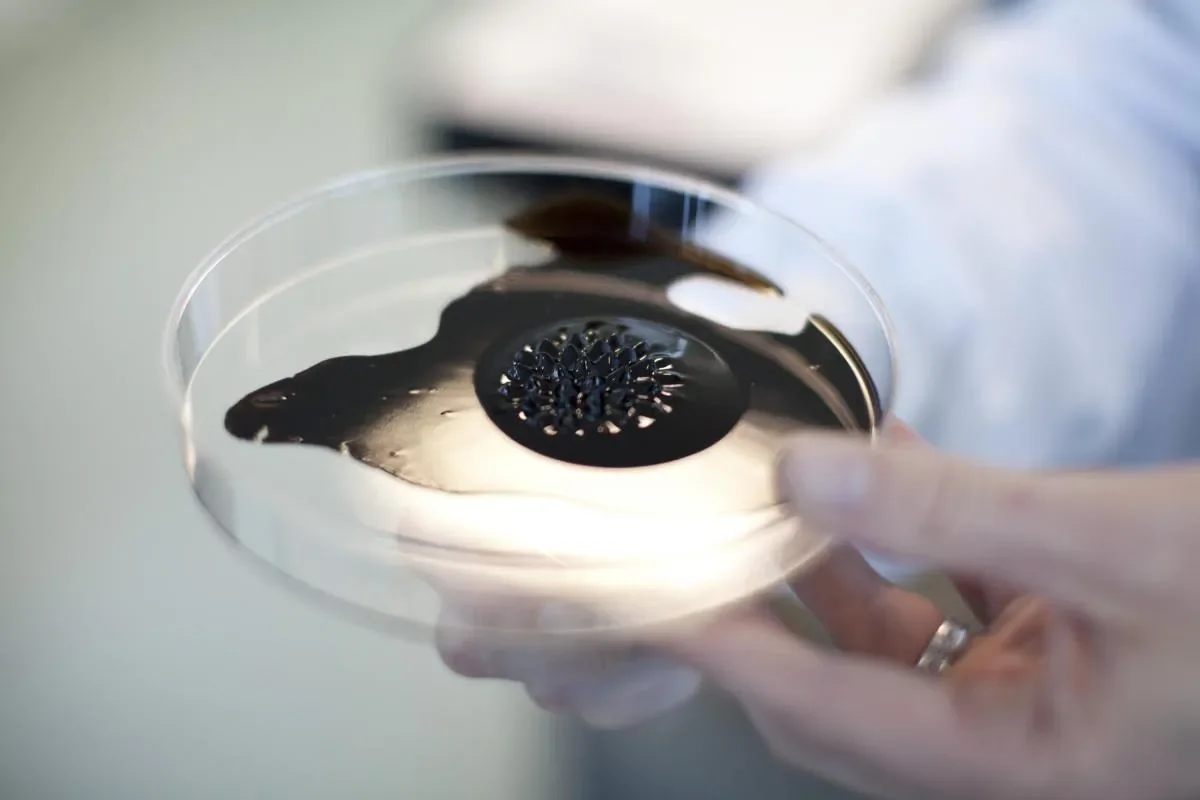

The project will investigate the feasibility of manufacturing magnesium-based medical implants using state-of-the art metal 3D printing and coating processes. Ultimately, the aim is to demonstrate improved implant performance while developing a novel, cost- effective, advanced manufacturing process.

Prof Nicholas Dunne said,

“This four year research programme is an exciting continuation of a long-term, fruitful research partnership between DCU and PBC BioMed. The advanced manufacturing expertise across the I-Form Centre will bring significant additional value to the programme. In particular, the access to expertise and cutting-edge equipment for metal 3D printing is essential to develop the next generation of these medical devices.”

Dr Tanya Levingstone said,

“Metal 3D printing is a digital-first advanced manufacturing process that facilitates rapid product development and unique designs that are not possible using traditional techniques. The 3D printing of magnesium alloys is a relatively new area but the excellent mechanical properties and biodegradability make these materials exciting candidates for improved device performance in orthopaedic applications.”

Paul Burke, Managing Partner for PBC BioMed, said,

“PBC BioMed is celebrating its 10th year of partnering with companies large and small, to deliver science-based innovations in the medical device, biologic and pharmaceutical sectors. This long-term engagement with I-Form forms a critical part of our R&D product and technology roadmap process. The SFI Centre - industry engagement model allows us to access the best expertise and equipment in academic institutions. Development of our R&D platform will help drive innovation and sustainability.”

*******************

About I-Form

I-Form, the SFI Research Centre for Advanced Manufacturing, is delivering the next level of understanding and control for complex manufacturing processes. Its mission is to shape the future of manufacturing through high-impact research into the application of digital technologies to materials processing. I-Form brings together a nationwide pool of expertise in materials science, engineering, data analytics and cognitive computing. I-Form is applying exciting developments in digital technologies to materials processing, to improve understanding, modelling and control, thus increasing the competitiveness of Irish manufacturing on the world stage. Funded by Science Foundation Ireland, I-Form works with industry to advance the low-cost, low-risk design of new products and the manufacture of high-value components exhibiting enhanced material performance, while reducing processing times and achieving enhanced process reliability. I-Form is actively engaged across a range of different materials processing technologies, with a particular focus on Additive Manufacturing (3D printing). I-Form is funded through the Science Foundation Ireland Research Centres Programme and co-funded under the European Regional Development Fund. It is a partnership between University College Dublin, Dublin City University, Trinity College Dublin, Institute of Technology Sligo, the National University of Ireland Galway, Waterford Institute of Technology and the National University of Ireland Maynooth - along with strong collaborative industry engagement in sectors that include medical devices, aerospace, automobile and microelectronic components.

See http://www.i-form.ie/ for more information.

About PBC BioMed

PBC BioMed was founded in 2010. The company partners with MedTech Companies to advance and maintain medical products helping create and bring to market products that provide real value and benefit to patients and practitioners globally. Our expertise and knowledge help companies in Accelerating Medical Innovation.